Creation Willi Geller Workbook - 1

METAL FRAMEWORK

The metal framework should be ground

with tungsten carbide cutters or fine - grained ,

ceramic bonded stones ensuring that the rotary

instrument is always moved in the same

direction . Make quite certain that no parts of

the metal become overlapped during trimming .

The framework should be sandblasted with aluminium oxide

( precious metal - 110 my , non - precious metal -

250 my , at a pressure of 2-3 bars ) and then

steam - cleaned or cleaned and degreased .

Oxidize the framework according to the manufacturer's instructions .

Ensure that the oxide layer is uniform .

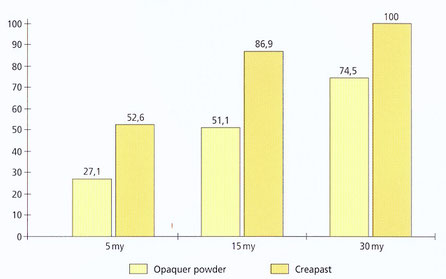

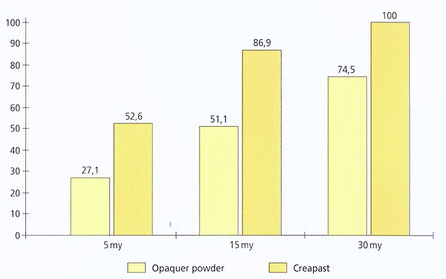

1st OPAQUER FIRING

Use the ”Creapast” Brush to apply the ”Creapust"

to the metal framework, ensuring that the

brushstrokes are even and that the metal is

masked by approximately 75%. Make certain

that the brush is only very slightly moist.

The first firing is carried out at 980 °C (non-precious alloys: 1000 °C),

in vacuum. Once the final temperature

has been attained, the firing chamber is vented.

Hold-time: 1 minute.

It is absolutely essential to pre-dry the

framework for 6 minutes at 550 °C.

After firing, the opaquer should have a slight sheen.

2nd OPAQUER FIRING

The second coating of opaquer should mask the metal completely .

If necessary , the opaquer shade can be adjusted

slightly with special opaquer modifiers .

( Opaquer powder from the "Creation"

Assortment may also be used for the second

opaquer coating ) .

The second opaquer firing is carried out at 950 ° C , in vacuum .

Once the final temperature has been attained ,

the firing chamber is vented once again .

Hold - time : 1 minute .

It is absolutely essential to pre - dry the

framework for 6 minutes at 550 ° C .

After the second firing , the opaquer should have an egg - shell finish .

Technical tips :

• The Creapust Brush must only be moistened slightly for use !

• Never dilute Creapast with water !

• The consistency of Creapust can only be adjusted slightly with UNIVERSAL FLUID ( UF ) from the Suprise Assortment !

• Avoid drying the material too quickly prior to and after placing it in the firing chamber ( bubbles due to boiling ) !

• Extruded material must not be drawn up into the syringe again !

• It is essential to pre - dry for 6 minutes at 550 ° C ( except when using an Ivoclar P90 = 400 ° C ) !

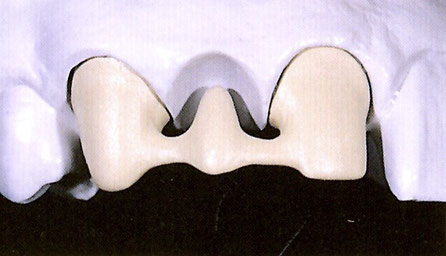

APPLYING THE OPACIOUS DENTINE

Seal the surface of the alveolar ridge beneath the pontics

using cyanoacrylate or lacquer and then apply

the separating agent with a" Crea - Pen"

The opacious dentine conceals the thin marginal area of the crown

and prevents excessive shadow effect penetrating the porcelain , including the interdental spaces .Opacious dentine also vitrifies to a slightly higher degree , thus making it more homogeneous and hygienic from the periodontal point of view .This is also very significant as far as the underside of the pontic is concerned and , in addition , stabil izes the shade of the cervical third of the crown .

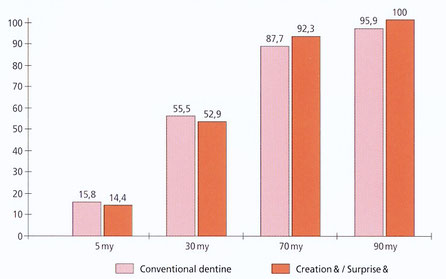

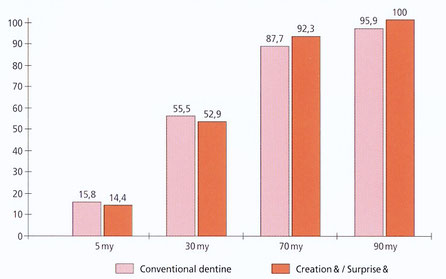

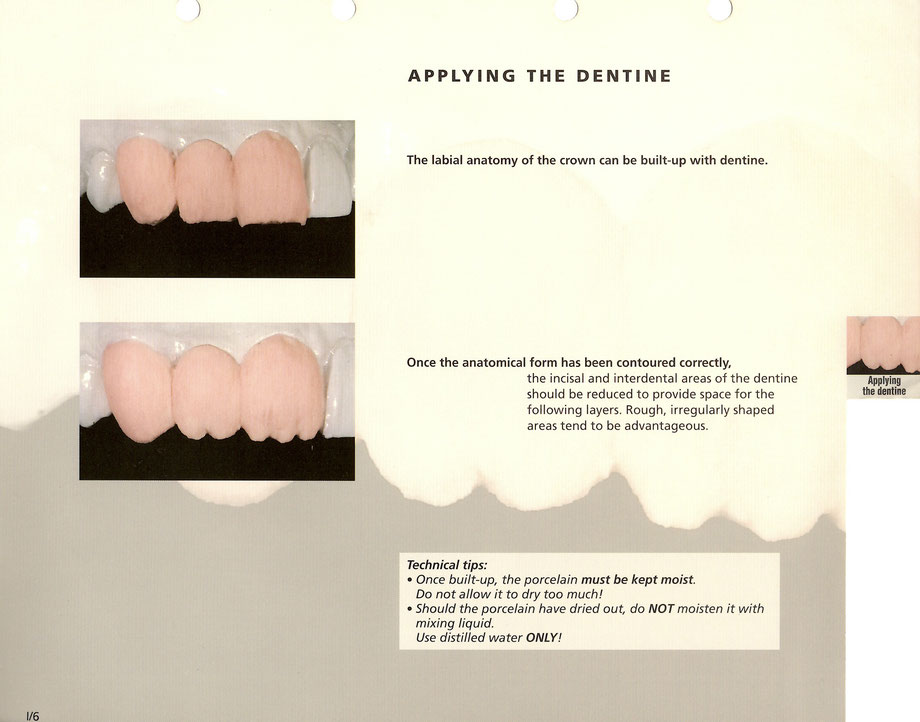

APPLYING THE DENTINE

The labial anatomy of the crown can be built - up with dentine .

Once the anatomical form has been contoured correctly ,

the incisal and interdental areas of the dentine

should be reduced to provide space for the

following layers . Rough , irregularly shaped

areas tend to be advantageous .

Technical tips :

• Once built - up , the porcelain must be kept moist .

Do not allow it to dry too much !

• Should the porcelain have dried out , do NOT moisten it with

mixing liquid .

Use distilled water ONLY !

APPLYING THE INCISAL PORCELAIN

The incisal aspect of the dentine layer is then extended vertically

with incisal and transparent porcelains and

contoured as required . The porcelain should

not be condensed whilst being built - up .

The dentine , in comparison to the adjacent

teeth , should be slightly over - extended

vertically .

Once the restoration has been released from the model ,

the contact areas are built - up with the

appropriate dentine , opacious dentine

and incisal porcelains and the interdental

spaces separated with a sharp instrument

( razor blade , thin scalpel etc. ) .

The first dentine firing is carried out at 920 ° C , in vacuum .

Once the final temperature has been attained ,

the firing chamber is vented .

Hold - time : 1 minute .

The only reliable method of ascertaining

whether the porcelain has been fired properly

is to view it after firing . If it appears like the

illustration opposite ( slightly glazed ) , the firing

cycle was correct .

2nd DENTINE FIRING

The bridge should be trimmed and cleaned

before adding further porcelain .

The 2nd dentine firing is intended for adjusting

the form of the bridge units only . Only small

adjustments are made to the form .

This firing is carried out at 910 ° C , in vacuum .

Once the final temperature has been attained ,

the firing chamber is vented once again .

Hold - time : 1 minute . If the porcelain has been

fired properly , it will also appear slightly glazed

after this firing .

Usually , only minimal adjustments have to be made to the form .

It is important that the surface morphology of

the restoration appears natural . It should

harmonize aesthetically with the adjacent

teeth , which can be achieved with standard

tungsten carbide cutters .

GLAZING

Once the bridge has been trimmed and cleaned ,

special effects can be added using the stains which are applied like water colours .

These stains are matched to one another

accurately and can be used to apply effects such as interdental or apical discolouration .

Glazing is carried out at 930 ° C , in air and with no hold - time .

This porcelain tends to exhibit a slight sheen only ,

which adds to its vitality .

The glaze of the restoration can also be matched to that in the mouth by polishing it with pumice and Sidol .

" Creation" restorations reproduce shades absolutely accurately

and create a brilliant , iridescent effect even

though they are easily built - up .

Creation -porcelains also exhibit exactly the right degree

of fluorescency which , even under extreme lighting conditions , enables the restoration to blend absolutely naturally and harmoniously with the residual dentition .

For further details , please refer to the

"Creation" - firing chart and shade determination chart .

FIRING INSTRUCTIONS

Preheat temp.. Drying time

Raise of temp. Vakuum

Final temp. Holding time

Appearance

OXIDATION

refer to the alloy manufacturer's instructions

1st OPAQUER FIRING

Creapast *

Pulver-Powder opaquer

550°C.. 6min

600°C.. 6min

80°C/min. .... ..yes

80°C/min. .... ..yes

980°C.. .1min

980°C.. .1min

slight shining

2nd OPAQUER FIRING

Creapast *

Pulver-Powder opaquer

550°C.. 6min

600°C.. 2min

80°C/min. .... ..yes

80°C/min. .... ..yes

950°C .. .1min

950°C .. .1min

Egg-shell shining

1st AND 2nd

SHOULDER FIRING

600°C.. 2min

80°C/min. .... ..yes

950°C.. .1min

slight shining

1st DENTINE FIRING

580°C.. 6min

55°C/min. .... ..yes

920°C.. .1min

slight shining

2nd DENTINE FIRING

580°C.. 4min

55°C/min. .... ..yes

920°C.. .1min

slight shining

GLAZE FIRING

600°C.. 2min

55°C/min. .... ..ー

930°C .. .ー

shining

POST SOLDERING

(Lot 800 °C)

600°C.. 2min

55°C/min. .... ..ー

850°C .. .ー

* when firing onto non-precious alloy: final temperature 1000 °C

* Ivoclar Programat P90/P95: 400 °C Preheating temp. Creapast

• The soldering investment should be as small as possible. Dry it in a preheating furnace for 10-20 min. at 200 °C. Then transfer the model to the porcelain furnace.

Once the soldering cycle has been completed, the soldered restoration must be removed from the furnace immediately. It is important that the restoration be cooled rapidly

after soldering!

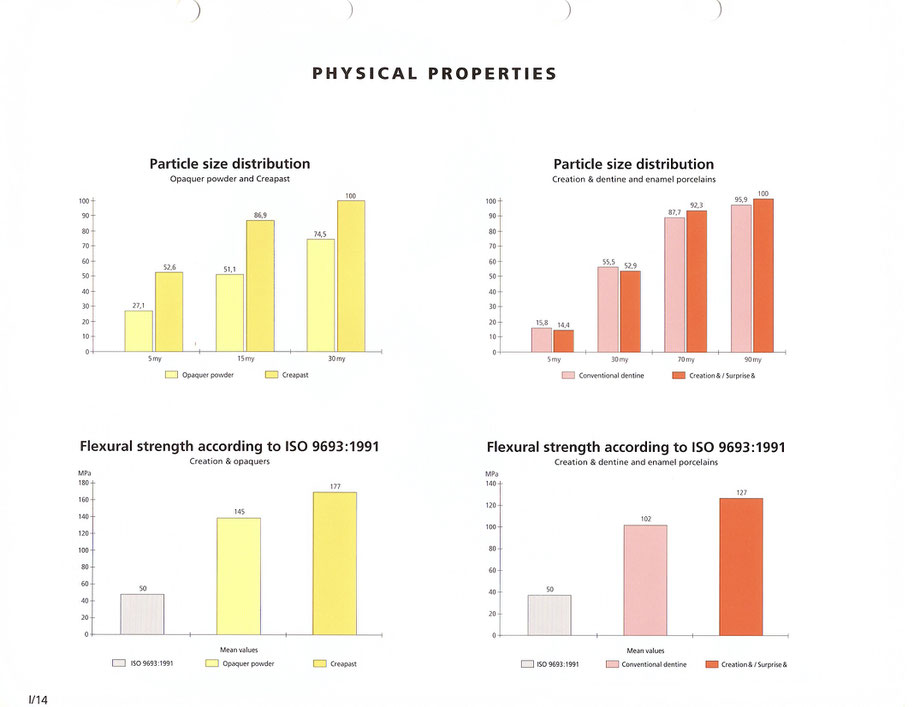

PHYSICAL PROPERTIES

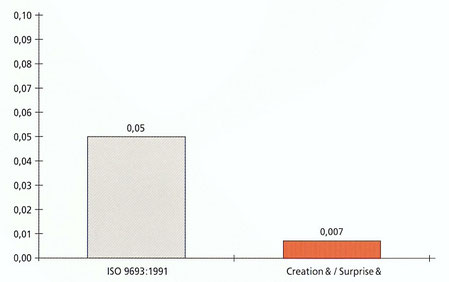

Bond strength according to ISO 9693:1991

All Klema products are of the highest possible quality and provide maximum reliability for the dentist , laboratory and patient .

ISO 9001 is an internationally recognized quality assurance system .